Reduce maintenance costs by implementing a proactive preventive maintenance scheme.

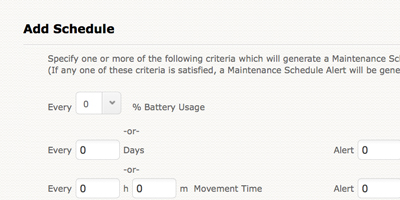

Preventive maintenance is essential in controlling equipment repair and maintenance costs. But when your equipment is continually on the move, and the operational parameters (distance, time lapse, operating time, etc.) are different for different equipment, staying on top of maintenance can be a challenge. With Fleetilla you can define the maintenance activity and operating threshold for each piece of equipment or equipment group. Once your schedule is active you’ll receive equipment-specific status reports and maintenance alerts.

Download equipment fault codes and reduce turn-around times in case of breakdown.

With our optional add-on modules, your Fleetilla system can capture and send engine trouble codes/DTCs and other essential data from both light-duty (OBDII) and heavy-duty (J1939) equipment. Such information can provide advance warning of impending breakdowns. Historical analysis of this data can help determine causes of specific or chronic malfunctions affecting equipment or equipment types.

With our optional add-on modules, your Fleetilla system can capture and send engine trouble codes/DTCs and other essential data from both light-duty (OBDII) and heavy-duty (J1939) equipment. Such information can provide advance warning of impending breakdowns. Historical analysis of this data can help determine causes of specific or chronic malfunctions affecting equipment or equipment types.

Investigate incidents/accidents using data extracted from the incident buffer

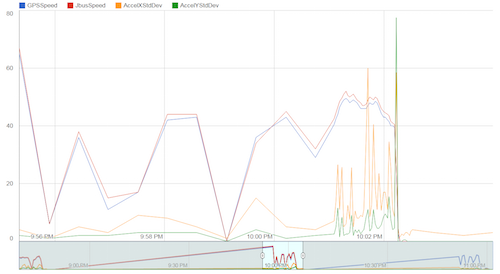

Many Fleetilla telematics hardware devices contain an incident buffer that maintains critical equipment parameters with extremely fine time resolution. This information is typically available for several weeks and can be extracted from the equipment's tracking device and analyzed to provide a precise picture of the circumstances surrounding a reported incident.

Many Fleetilla telematics hardware devices contain an incident buffer that maintains critical equipment parameters with extremely fine time resolution. This information is typically available for several weeks and can be extracted from the equipment's tracking device and analyzed to provide a precise picture of the circumstances surrounding a reported incident.